Product Description

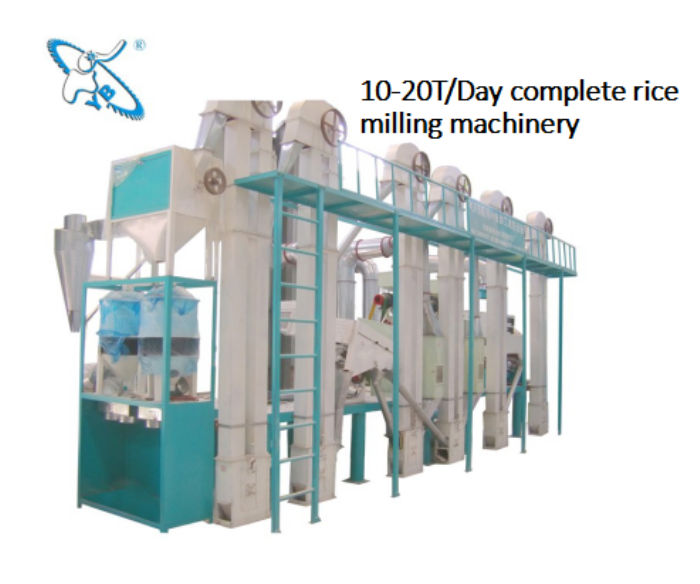

Product DescriptionRice Milling process:

1. Cleaning part

Bucket Elevator is mainly used to transport millet in complete processing line.

The magnetic separator is to remoq21ve the metal from the material.

Then the paddy will be transfered into the combine screening and destoner to remove the large and light impurities and stone.

2. Milling part

Next, the rice into the paddy husker to remove the shell.

It can separate the shell from the paddy husk mixture through the suction effect.

Paddy separating screen used to separate the brown rice and rice.

Rice machine is adopted to peel the rice and brown rice.

The rice that has removed the shell will be into the rice milling machine for further processing.

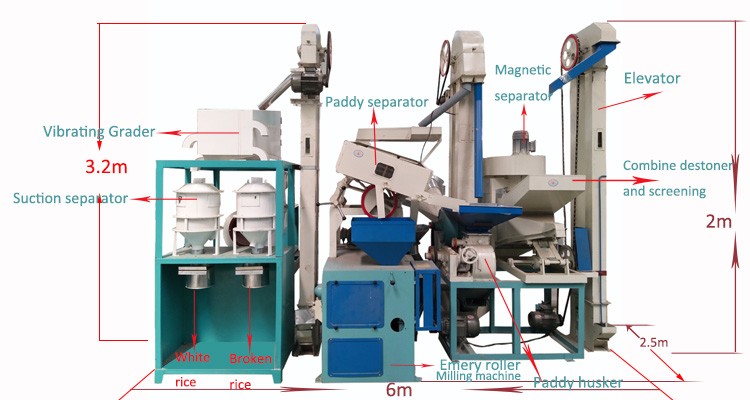

3. Grading and Packing part

Aftger grading ,the rice will be graded two parts, whole rice and broken rice, and all will be packed.

Features:

1.Beauty installation structure

2.Out rate of rice guarantee

3.Less Worker labor

4.High efficient

Packing & Delivery

Packing & Delivery Certifications

Certifications Our Company

Our Company

Our Service

Our Service| Per-sale | Win-win cooperation: 1. Sign the contract 2. Establish mutual benefit, strategic cooperative partnership. | ||||

| After-sale | Technical service: Long time technical service Accessories supplying: Supplying spare parts with cost Complaint handling: 12-24 hours response mechanism Client Review: 1. Call-back 2. Regular return visit. | ||||

Place of Origin:Henan, China

Brand Name:YuBei

Production Capacity:1 t/h

Voltage:220V/380V

Power(W):19.85kw

Weight:2T

Dimension(L*W*H):6*2.5*3.2m

Certification:ISO9001

Warranty:1 YEAR

After-sales Service Provided:Field installation, commissioning and training, Engineers available to service machinery overseas

Product name:Rice Mill Machine

Function:mill brown rice

Color:White

- Packaging Details

- plywood case

- Port

- ShangHai;QingDao;TianJin