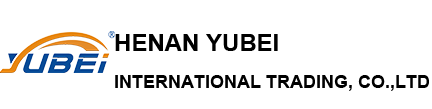

Hot Selling 150TPD Quinoa Processing Machine

Product Application

1.Bucket Elevator is mainly used to transport quinoa in complete processing line.

2.The magnetic separator is to remove iron, iron pin from the material.

3.Vibrating Screen is specially used for separating the impurities from quinoa.

4.After cleaning, quinoa will be transported into Proportion Stoner to separate the stone.

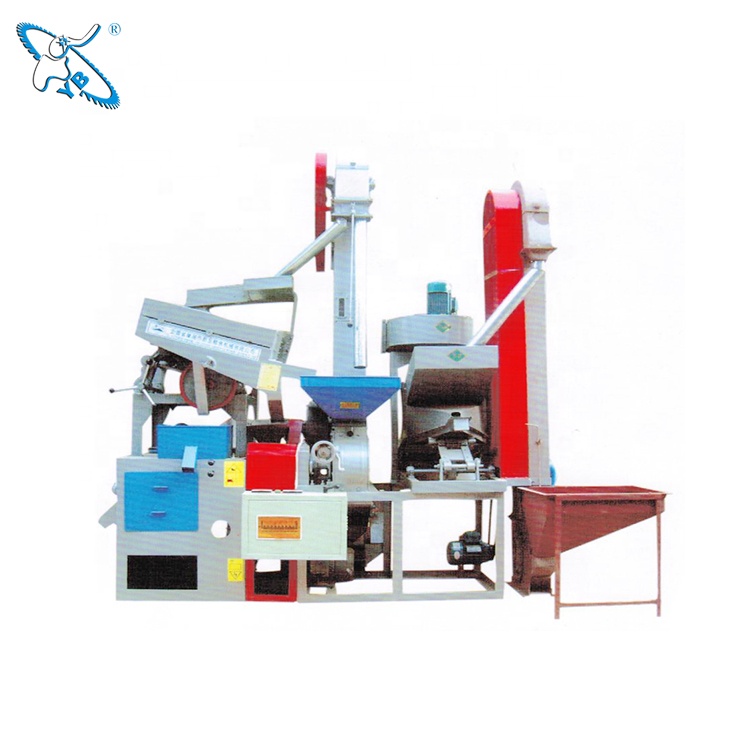

5.Next, the quinoa into the Hulling Machine to remove the shell.

It can separate the shell from the paddy husk mixture through the suction effect.

6.Paddy separating screen

7.Quinoa peeling machine

8. The quinoa that has removed the shell will be into the Polishing Machine.

The machine is mainly used for cleaning the quinoa to make them look brightly. It is one of the key processing millet.

9.Friction polishing machine is mainly used to make further the polishing.

10.Suction separator used to separate hull,dust and other impurities.

11.Out from thesuction separator ,the quinoa into the Color Sorter to get more high quality quinoa, black quinoa and break quinoa will be passed

12.Finally,we will use the automatic packing machine to pack the rice.

Notes: The skin of the quinoa tastes very bitter, so during the processing, it must be polished sometimes to remove the skin.

| Type | 5T | 10T | 20T | 30T | 50T |

| Capacity(t/d) | 5 | 10 | 20 | 30 | 50 |

| Power(kw) | 20 | 57 | 72 | 94 | 143.19 |

| Installation Area | 5×3×3.2 | 10×5×4.5 | 11×5×4.5 | 12×5×5.5 | 1×6×5.5 |

LETTER OF PATENT

ZL201720543664.1

Specialized in Quinoa processing line

Packing & Delivery Our Company

Our Company Certifications

Certifications Our Service

Our ServicePre-sale | System evaluation: 1. Project basic situation Solution: 1. The investment budget 2. Site measurement 3. Technical discussion Product selection: 1.Factory inspection 2. Site measurement 3. Technical discussion 4. Supply professional drawing and lists Win-win cooperation: 1. Sign the contract 2. Establish mutual benefit, strategic cooperative partnership. |

In-sale | Design evaluation: 1. Detailed technical assessment, arrangement 2. Design of process and equipment layout Procurement: Strictly inspection, optimized selection. Installation: 1. Quality and quantity guaranteed 2. Completion of hand over Acceptance: 1. Acceptance test 2. Accepted deliverable Technical training: 1.On-site installation and products training 2. Operation skills training 3.Maintenance training 4. Centralized technical training. |

After-sale | Technical service: Long time technical service Master device:Free supply during the warranty Accessories supplying: Supplying spare parts with cost |

Q1.What's your advantage? Why we choose you?

A:20 Years experience of design and manufacture grain and oil machinery.We have the most professional techniques and team. More advantage in price.

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. L/C could also be accept, but the procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4: Can you show how the machine works?

A: Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better.

Q5: How can I know your machine works well?

A: Before delivery, we will test and adjust the machine working condition for you, then you can use directly when you get it.

Q6: Do you have ISO certificate?

A: For every model of machine, it has a ISO certificate.

Use:Pressing Quinoa

Certification:ISO

Place of Origin:Henan, China

Brand Name:Yubei

Condition:New

Name:quinoa processing machine

Production Capacity:50T

Material:Carbon steel

Color:white

Raw material:quinoa

Application:Food Processing Units

Usage:Industry

Feature:Low Energy High Speed

Final product:fine quinoa

Patent No.::ZL201720543664.1

After-sales Service Provided:Engineers available to service machinery overseas

- Packaging Details

- Shipping container

- Port

- Shanghai,Qingdao,Tianjin

- Lead Time :

-

Quantity(Sets) 1 - 1 >1 Est. Time(days) 30 To be negotiated